In die casting, low-pressure casting and gravity casting (including sand/metal type), CAE simulation is used as the core digital tool for coupled numerical simulation of the whole casting process by constructing a three-dimensional model covering the mold, casting and sprue system. Its common core analysis module includes:Charging process simulation(Analyze liquid metal flow patterns, predict cold segregation and gas wrapping),Solidification process simulation(analyzing temperature field and solidification sequence, predicting shrinkage) andStress/deformation simulation(Prediction of thermal stresses, residual stresses and deformations). For process characterizationDie casting CAE focuses on high-speed mold filling and air roll analysis, mold heat balance and cooling optimization.;Low-pressure casting CAE focuses on precise control of air pressure field, sequential solidification and shrinkage simulation.;Gravity casting CAE focusing on natural flow regime under gravity, solidification paths and riser make-up efficiency assessmentThe fundamental role is to scientifically predict defects and optimize process parameters and mold design. The fundamental role is to scientifically predict defects, optimize process parameters and mold design to significantly improve casting quality, shorten development cycles and reduce trial and error costs.

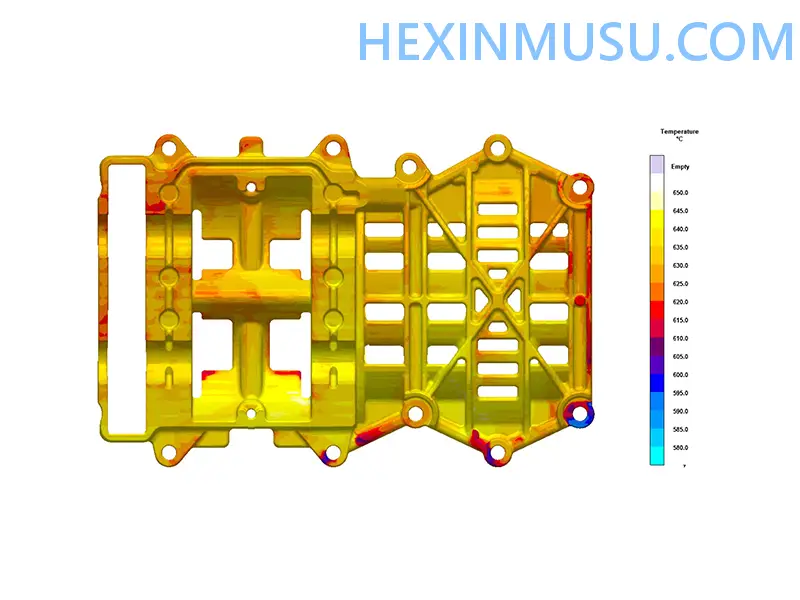

temperature simulationCAE Simulation Aluminum Casting Temperature Simulation

Filling flow simulationCAE Simulation of Aluminum Casting Filling Flow Simulation

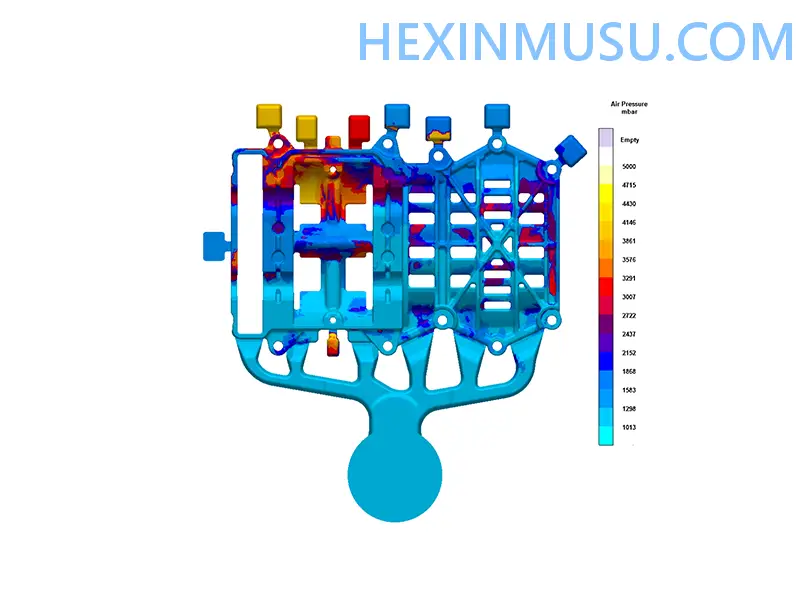

Barometric Pressure Simulation AnalysisCAE Simulation of Aluminum Casting Volume Gas Simulation Analysis

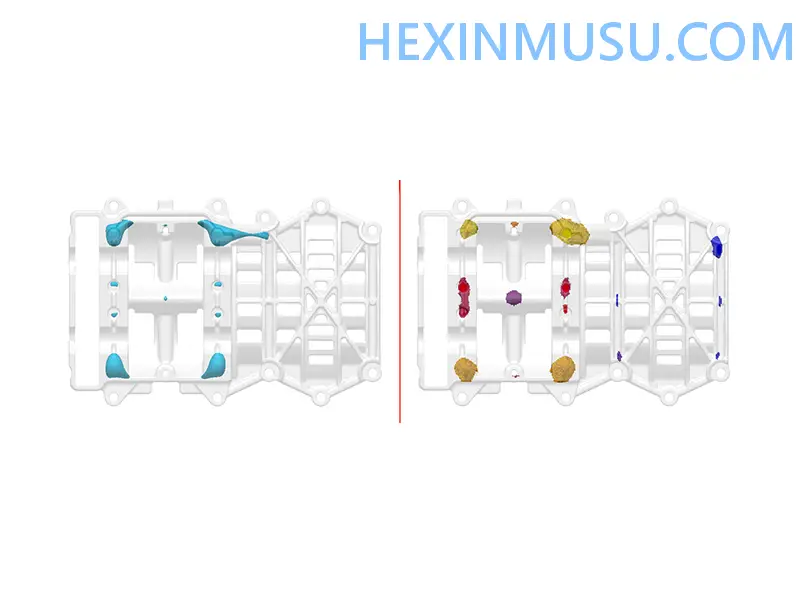

Shrinkage simulationCAE simulation of aluminum casting shrinkage simulation